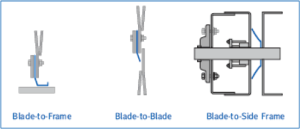

Depending on the degree of isolation desired, the damper can be equipped with an assortment of flexible and non-flexible seals. The range from our base Step Seat to our “Full Set” of engineered seals which include Blade-to-Side Frame (Jamb), Blade Overlap, and Blade-to-Frame (Top/Bottom Sweep).

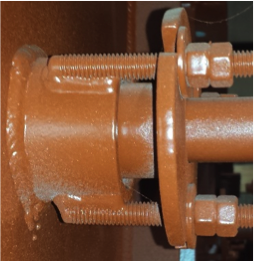

Our line of Louver dampers provides reliable modulation and isolation. All designs are heavy-duty and have either an airfoil or box-style (internally stiffened) blade profile, outboard bearings, and individual packing glands to achieve minimal to zero leakage around the shafts. Our designs offer quick response and fast operating cycles. The Louver damper is capable of providing accurate and repeatable flow control for all applications. 100% isolation can be achieved with the Double Louver damper which is equipped with a Seal Air System consisting of a pressure blower, a small bit of ducting, and a fabricated shutoff damper.