Flextech can include most types of actuation requirements, i.e. electric, pneumatic, manual, etc…, as well as accommodate other requirements such as an extended shaft or mounting of a customer supplied device.

Inlet Vane dampers are used to modulate the flow/pressure relationship of a blower from the inlet side. They are sometimes referred to as Variable Inlet Vanes (VIV) or Internal Vane Controls (IVC). They are suitable for applications requiring both fan shutoff and volume control. Inlet Vane dampers exploit the properties of fans by affecting the rotation of the air entering the fan to reduce fan pressure without degrading the speed.

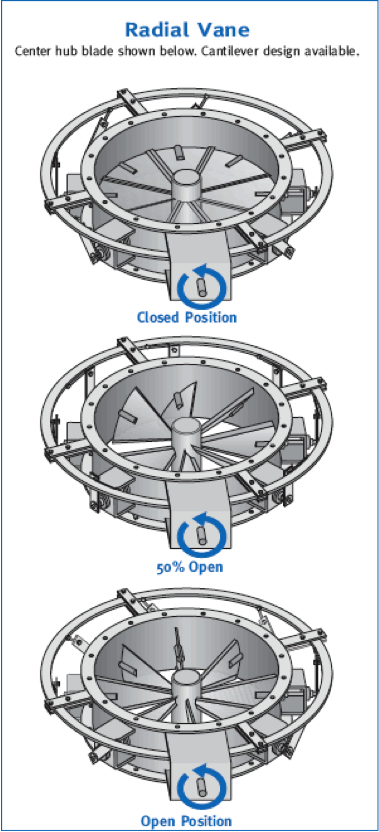

When an inlet vane is partially closed, each blade directs the air into the wheel in the direction of rotation and so the air is pre-spun. This brings about a reduction in the Capacity, Static Pressure and BHP. The amount of BHP savings at reduced capacity is determined by the type of system and type of fan-vane combination.

Inlet Vane dampers are typically supplied using a center hub design (for clean air applications) but can be supplied without the hub (called Cantilevered) for dirty applications. Inlet Vane dampers are also usually a flanged design which bolts to the fan’s inlet flange but can also be supplied as a nested style in which the damper is built around the throat of the inlet cone.

The “Center Hub” version has multiple blades arranged around a central hub enhancing the performance of the fan by introducing swirl into the fan inlet providing an efficient method of control. In cases where there is particulate flowing through the system, a “Cantilevered” design, without the center hub, is available. Either design is engineered to ensure ease of maintenance and service without removing the damper from the fan and designed to withstand the high air velocities that can be experienced in use.