Flextech can include most types of actuation requirements, i.e. electric, pneumatic, manual, etc…, as well as accommodate other requirements such as an extended shaft or mounting of a customer supplied device.

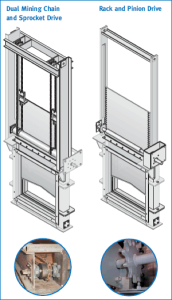

Our line of Guillotine dampers are preferred in applications where isolation is critical and services conditions can be severe. The frame is constructed of a heavy structural channel with cross bracing to withstand all drive thrusts, wind, and handling loads without additional supports. Frame mounted bearings support a torsionally rigid sprocket/torque tube assembly by utilizing high-strength, corrosion-resistant stub shafts and our machined “Pocket” Sprocket design.